How does the screw head shape form?

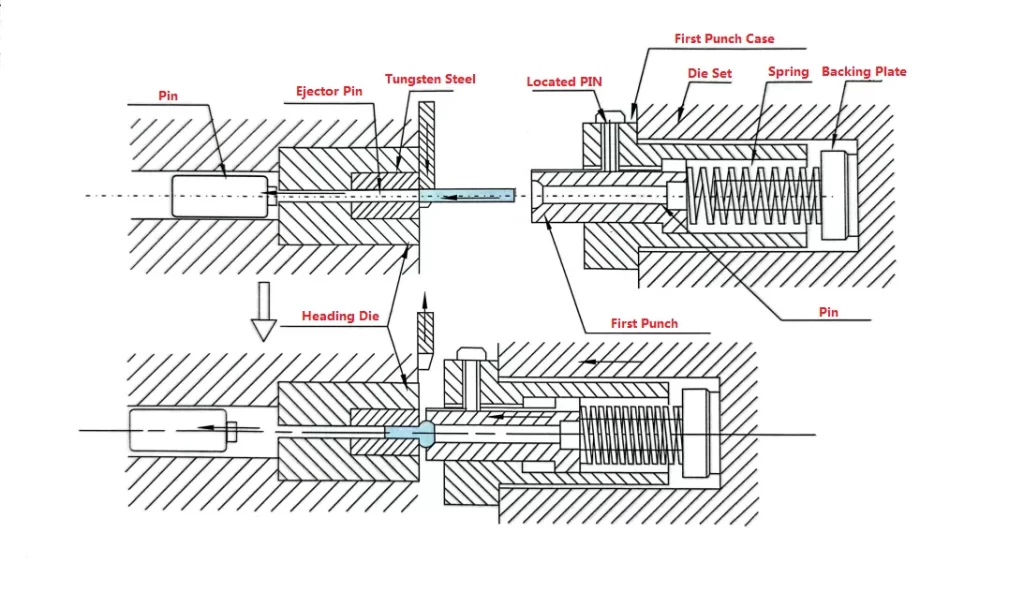

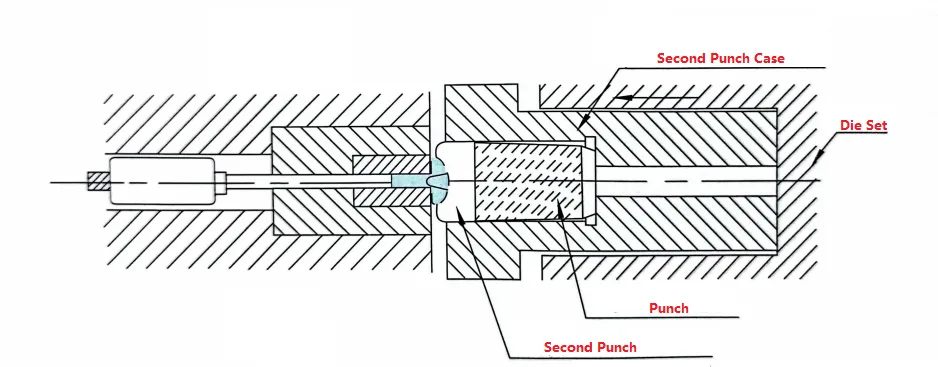

What is a header die?

A header die is a fundamental part of cold forming. It is used to form the screw head shape in this process, which includes carbide heading die, shearing die, die cutting blade, screw first punch die, screw second punch die, pins, and so on. Moreover, the selection of the materials for the header die is crucial, and the service life depends on the quality of the tungsten steel inside.

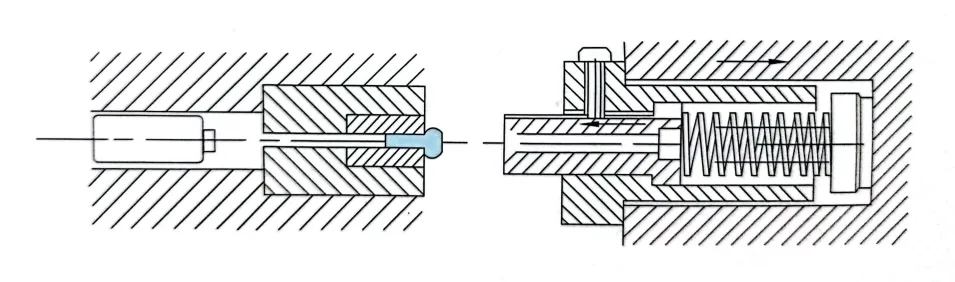

How do the screw head and screw drive form?

This machining process is called cold heading, also known as cold forming or cold working.Cold heading is one of the new pressure process with non-cutting metal. Cold heading process is most suitable for the production of fasteners, such as bolts, screws, nuts,rivets,and pins.

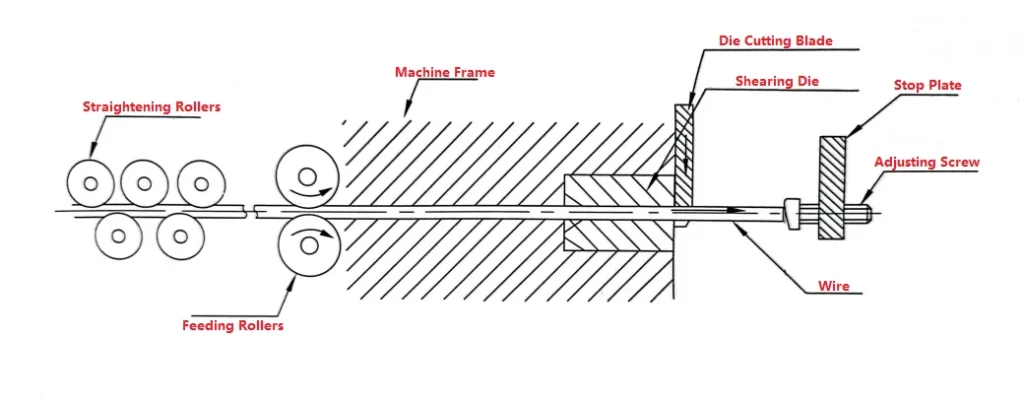

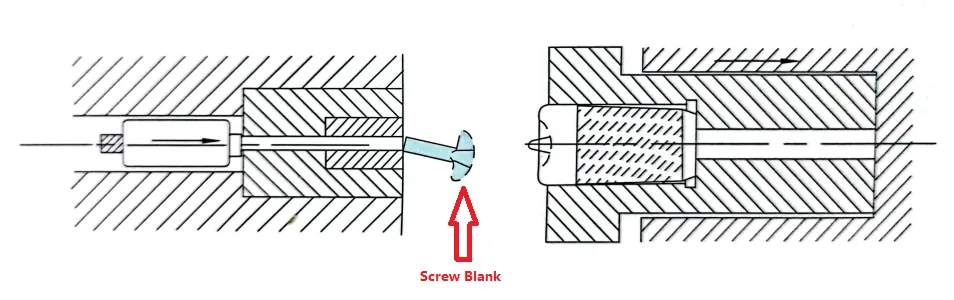

Firstly, the wire is fed from the mechanical coil through a pre-straightening machine, in which the straightening rollers are responsible for straightening the wire, and the feeding rollers are in charge for feeding the wire. Once straightened, the wire flows directly into the shearing die that the die cutting blade automatically cuts the wire at a designated length.