What is Injection Molding?–Definition, Types, and Materials

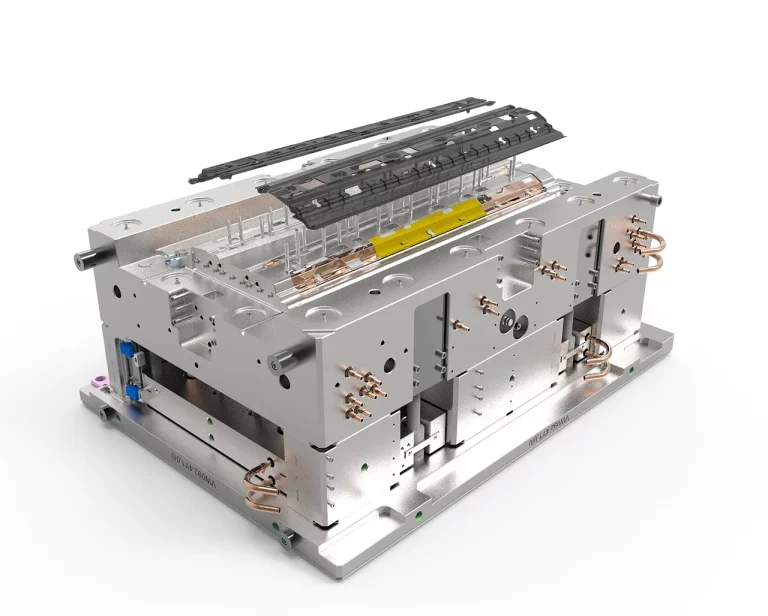

What is Injection Molding?–Definition, Types, and Materials What is Injection Molding? And How does Injection Mold work? Injection molding (or Injection Moulding) is a manufacturing process used to produce parts and products by injecting molten material into a injection mold cavity. The process typically involves the following steps: Clamping: The two halves of the mold, the stationary side, and the moving side are securely closed together under high pressure. This creates a sealed mold cavity. Injection: Molten material, usually in the form of thermoplastics, is injected into the mold cavity through a injection molding nozzle. The material fills the cavity, taking its shape and conforming to the mold’s contours. Cooling: After the material is injected, it is allowed to cool and solidify within the mold. Cooling…