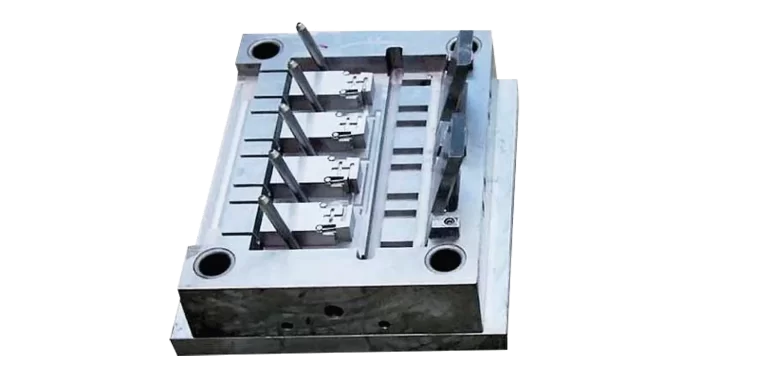

Custom Tungsten Carbide Parts: Delivering High-Quality Solutions for Your Needs

Custom Tungsten Carbide Parts: Delivering High-Quality Solutions for Your Needs What is Tungsten Carbide? Tungsten carbide is a composite material comprised of tungsten (W) and carbon (C) atoms. Known for its exceptional hardness and wear resistance, tungsten carbide is often used in applications that demand high performance and durability. It is produced through a powder metallurgy process where tungsten carbide grains are bonded together using a metallic binder,typically conalt (Co).The resulting material exhibits superior strength, toughness, and resistance to wear, making it ideal for applications subjected to extreme conditions. What are the Properties of Tungsten Carbide Parts? Exceptional Hardness: Tungsten carbide parts exhibit remarkable hardness, surpassing that of most other materials. This hardness provides excellent wear resistance and extends the lifespan of carbide components, even in highly abrasive environments. Superior…