CNC Milling Services

*Materials including metals and plastics

* Tolerances down to +/-0.01mm

* Global delivery as fast as 3 days by UPS, DHL, FedEx

Capabilities+Features

| Flexible customization | High Quality Assurance | Solution | Experience |

| Customized materials Customized surface treatment Custom surface finish |

(Every)Piece inspection | Combined process plan of turning,milling and grinding Production cost control scheme |

20+experience in machining industry Customers are all over Europe America and Asia |

According to the CAD drawing of the product, CNC milling machine can process circles, end faces, radian, groove teeth, tapping, etc. CNC milling machine has at least three axes control system, up to five axis CNC machining, using different tools to mill workpieces from multiple angles simultaneously. It manufactures complex and high precise milled parts faster than a manual milling machine.

We provide CNC milling services to meet your production and design needs, from simple planes to complex geometries. We also provide quality inspection report, material certificate, heat treatment certificate, and surface treatment certificate.Our state-of-the-art CNC milling center machines a variety of materials, including carbon steel, alloy steel, high speed steel, tungsten steel, stainless steel, copper, aluminum, plastic, and so on. We can always choose the proper precision milling process to meet your requirements. Our custom CNC machining services ensure that our customers receive the highest quality CNC milling parts. Welcome to send your inquiry or drawing to get an online CNC quote.

CNC milling stroke and Tolerance

| Machine | Maximum Stroke(mm) | Maximum inner hole and deep size | Machining accuracy(mm) |

| CNC milling machine | 1100*600*350 | 600*120 | 0.01 |

| High Speed Milling | 1270*254*350 | 600*120 | 0.05 |

Minimum size for our CNC milling machining:

| Thickness | Hole | Internalthread | Groover width | External Raised chamfer | External concave chamfer | Internal Raised chamfer | Internal concave chamfer |

| 1.0mm | 0.5mm | M2 | 1.0mm | C0.1mm | C0.2mm | C0.1mm | C0.2mm |

Materials by Industry

| Hot Work Die Steel | 45# steel,Q235 material, SKD61 material, P20 material, 303 stainless steel, sus304 stainless steel, sus316 stainless steel, stainless steel 416, C260 material, C360 material, Copper Beryllium |

| Cold Work Die Steel | 45# steel,Q235 material, material SKS3, SKD11 steel, SKH51, ASP30 tool steel, ASP60 Tool Steel, ST6 material, ST7 steel, KG5, KG6 |

| Mechanical Automation | 45# steel,Q235 material, SKD61 material, material SKS3, SKD11 steel, AL5052, AL6061, AL6063, AL7075, 303 stainless steel, sus304 stainless steel, sus316 stainless steel, POM plastic, PEEK plastic, DELRIN plastic, NYLON plastic, plastic PVC, POLYSTYRENE plastic |

Partial ISO1302surface roughness chart

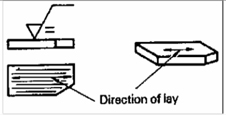

| Symbol | Interpretation | Example |

| Parallel to the projected plane of the view using the symbol |  |

|

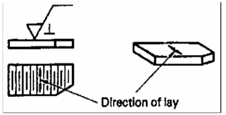

| Perpendicular to the projected plane of the view using the symbol |  |

|

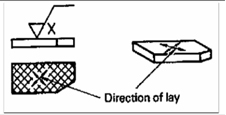

| X | Slanted and intersected within the projected plane of the view using the symbol |  |

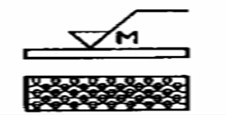

| M | Multi directional |  |

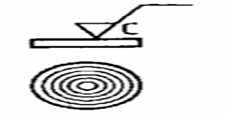

| C | Approximately concentric with respect to the center of the plane in which used by this symbol |  |

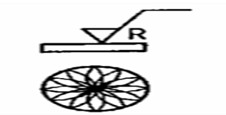

| R | Approximately radial in the plane used by this symbol with respect to the center of the plane |  |

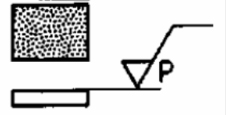

| P | The texture is grainy,non-directional,or raised |  |

FAQ:

- What products are suitable for CNC milling process?

It is suitable for processing workpieces of various structures and shapes. It can complete circles, end faces, radians, groove teeth, tapping, drilling, boring, reaming, milling planes, milling inclined planes, cams, surface contours, etc. - What are the differences between CNC milling machine and CNC machining center?

– The main difference is whether the device has a tool magazine.

– The machining center is a CNC milling machine with a tool magazine. The machining center can realize the automatic replacement of tools and complete multiple processing procedures in one clamping. Moreover, in the continuous processing process of multiple working procedures, the operator does not need manual intervention as long as the program is prepared, and the tool and the corresponding parameters are configured.

– Ordinary CNC milling machine has three feed axes and one rotary spindle. Its machining mode is almost the same as that of CNC machining center, which can basically achieve the same machining capabilities. The difference is that the tool must be changed manually when the process changes in CNC milling machine. So milling machine process is discontinuous and performed intermittently at multiple levels. - The method and process of metal heat treatment?

– The metal heat treatment process generally includes three steps: heating, heat preservation, and cooling.

– Metal heat treatment can be roughly divided into three categories: overall heat treatment, surface heat treatment, and chemical heat treatment.

* Overall heat treatment is to heat the workpiece as a whole and then cool it at an appropriate rate to change its overall mechanical properties. It roughly has four basic technologies for annealing, normalizing, quenching, and tempering. Generally, the cooling rate of annealing is the slowest, the cooling rate of normalizing is fast, and the cooling rate of quenching is faster. Annealing and normalizing are often referred to as preparatory heat treatments. It is mainly used in the blanks or semi-finished products of various casting, forging, and welding workpieces to eliminate the defects in metallurgical and thermal processing and to prepare an excellent micro-structural state for subsequent machining and heat treatment. The heat treatment, combining quenching and high-temperature tempering, is called quenching and tempering heat treatment. The purpose of quenching is to improve the strength, hardness, wear resistance, and other mechanical properties of steel to meet the different use requirements of various parts or tools. However, the quenched martensite structure obtained by the heat treatment quenching process is very hard and brittle, has high internal stress, and is easy to crack. Therefore, the quenched workpiece must be tempered before use.

*Surface heat treatment is only to heat the workpiece’s surface to change the mechanical properties of the surface. The main methods of surface heat treatment are flame quenching and induction quenching, and commonly used heat sources include flames such as oxyacetylene or oxypropane, as well as induced current, laser and electron beam technology, and so on.

* Chemical heat treatment is used to change the material structure and properties by changing the surface chemical composition of the workpiece. The main methods of chemical heat treatment are carburizing, nitriding, and metalizing. - How to buy?

First, make the product inquiry by Email or telephone, and after confirming the price, send us the order email that needed to be processed. - How to reduce the cost of a product?

After fully understanding the performance of the customized products, according to the requirements of quantity, material, heat treatment, and surface treatment,

– Under the premise of guaranteeing the use function, choose cheaper and more cost-effective materials.

– Selecting suitable processing technology can reduce processing time and processing costs.

– Choose an experienced processing master. You can deal with problems more experienced and timely when encountering problems, improve processing efficiency and reduce processing costs.

– The selection of high-quality tools reduces the time for frequent tool breakage, tool bounce, and replacement of new tools during processing, which can reduce processing costs. - where is the origin?

Dongguan City, Guangdong Province, China - How long is the usual processing cycle?

7~15 days after placing the order - What is the minimum order quantity?

One piece minimum order - How to place an order?

E-Mail - How to transport?

Air express (UPS, DHL, FEDEX, OCS…), Ocean freight - How to pay?

T/T - How to make an inquiry?

E-mail,Whats app, Skype - How to conduct quality inspection?

Digital calipers, micrometers, height measuring instruments, plug gauges, profile projectors, COORDINATE MEASURING MACHINE, industrial screws, thread gauges, dial indicators, ring gauges - How to packing?

Secondary Inspection——Wiping ——Bagging——Spraying Anti-rust Oil——Packing - How long is the shipping time?

Europe and the United States 3~7 working days, according to different express times

Japan 2~7 working days, according to different express time