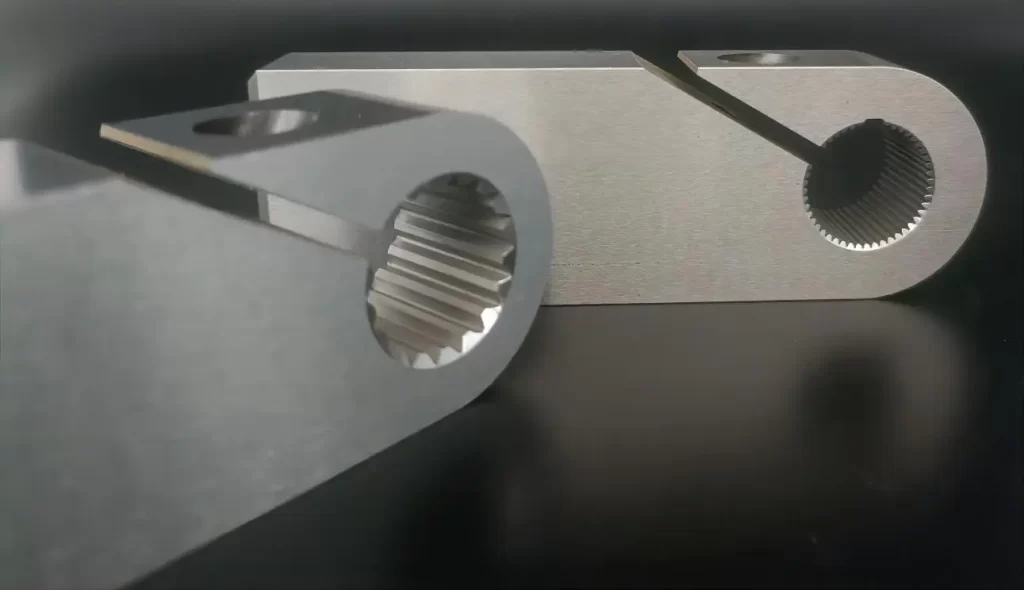

D2 Steel Machined Parts:Unleashing the Power of Precision

What is D2 Steel?

D2 Tool Steel is classified as high carbon tool steel due to its high carbon content, typically raning from 1.40% to 1.60%. It falls under the cold-work tool steel category. D2 tool steel is an ideal choice for precision machining applications thanks to its exceptional hardness, wear resistance, and dimensional stability.

What are the Typical Chemical Composition of D2 Steel?

The typical chemical composition of D2 Tool Steel includes:

| The typical chemical composition of D2 Tool Steel | |||||

| Carbon(C) | Chromium(Cr) | Vanadium(V) | Molybdenum(Mo) | Silicon(Si) | Manganese(Mn) |

|

1.40%-1.60% |

11.00%-13.00% | 0.70%-1.20% | 0.70%-1.20% | 0.10%-0.60% | 0.10%-0.60% |

Some Names of Steel D2 Commonly Used Worldwide

D2 tool steel goes by various names across the globe. Some of the well-known names include:

– AISI D2 Steel:

This is the standard designation for tool steel D2 according to the American Iron and Steel Institute (AISI).

– DIN 1.2379:

This is the European standard designation for D2 material according to the Deutsches Institut für Normung (DIN).

– JIS SKD11:

This is the Japanese Industrial Standard (JIS) designation for steel D2.

– GB Cr12Mo1V1:

This is the Chinese standard designation for tool steel D2 according to the GB/T 1299-2000 standard.

– SAE D2:

This is another common designation used for D2 tool steel, following the Society of Automotive Engineers (SAE) standard.

What Are the D2 Steel Heat Treatment?

D2 tool steel can undergo various Thermal Treatment processes to achieve desired mechanical properties. Its most common thermal treatments include:

Annealing: It is typically annealed to relieve internal stresses and improve machinability.

Hardening: Hardening, also known as quenching, is a critical step to increase the hardness and wear resistance of D2 tool steel.

Tempering: Tempering is performed after hardening to reduce the brittleness of D2 material and enhance its toughness.

Cryogenic Treatment: Cryogenic treatment helps to further refine the microstructure, reduce residual stresses, and enhance the steel’s dimensional stability and wear resistance.

What are the Typical D2 Steel Applications?

Steel D2 can be used to create a variety of parts, such as:

| Applications | Descriptions | Examples of Parts |

| Cutting Tools and inserts | Its high hardness and excellent wear resistance enable these tools to withstand the intense cutting forces and maintain their sharpness over extended periods. | drills, reamers, milling cutters, saw blades, etc. |

| Forming Tools and Molds | It can withstand the high pressures and abrasive forces involved in processes like forging, extrusion, and casting, ensuring accurate and consistent shaping of materials. | Forming Dies, Heading Tools, Shear Blades, etc. |

| Machine Components | D2 Tool Steel’s properties enable these components to operate under demanding conditions with minimal wear and deformation. | Gears, Shafts, Cams, and Bearings, among others. |

| Tooling for Metal Stamping and Extrusion Processes | It can withstand the repetitive forces and abrasive nature of these operations. | Punches, Dies, Tooling Inserts, etc. |

| Plastic Injection Molding | It can withstand the high temperatures and pressures involved in the plastic molding process while maintaining dimensional accuracy. | Molds, Inserts, etc. |

| Woodworking Tools | Its high hardness and wear resistance make it suitable for cutting and shaping wood with precision and longevity. | Chisels, Planer Blades, and Router Bits, etc. |