How is Progressive Die & Stamping Made?

What is Progressive Die Stamping?

Use this space to add a medium length description. Be brief and give enough information to earn a click.Progressive Die Stamping is a highly automated and efficient manufacturing process that allows for the mass production of consistency and complex precision parts. At U-Need, we specialize in providing progressive die stamping services, offering our customers a wide range of high-quality parts.

How is Progressive Stamping made?

Stock Strip Layout & Design:

The process starts with the design and layout of the stock strip.

The a metal material used to produce stamped parts. The strip layout involves arranging the part geometries in a way that maximizes material usage and optimizes production efficiency.

Progressive Tool and DieMachining:

Tool steels are machined to create the superior die set used in the progressive die stamping process.

The dies consist of multiple stations, each performing a specific operation, such as blanking, piercing, bending, or forming Precision mold design is to ensure the accuracy and repeatability of parts production.

Secondary Processing:Gringding & Heat Treating

Depending on the specific requirements parts, secondary processes may performed dies.

These processes can include grinding to achieve precise dimensions and heat treating to enhance the durability and hardness of the dies.

Wire EDM:

Wire Electrical Discharge Machining (EDM) is create intricate shapes and contours in the dies.

This process involves using a thin, electrically charged wire to precisely cut the desired shapes in the hardened tool steel.Wire EDM ensures the dies are capable of producing complex part geometries accurately.

Die Assembly:

The machined components of the dies are carefully assembled, ensuring proper alignment and functionality.The die assembly includes fitting various components, such as die punches, die cut inserts, and strippers,together to create a complete and operational die set.

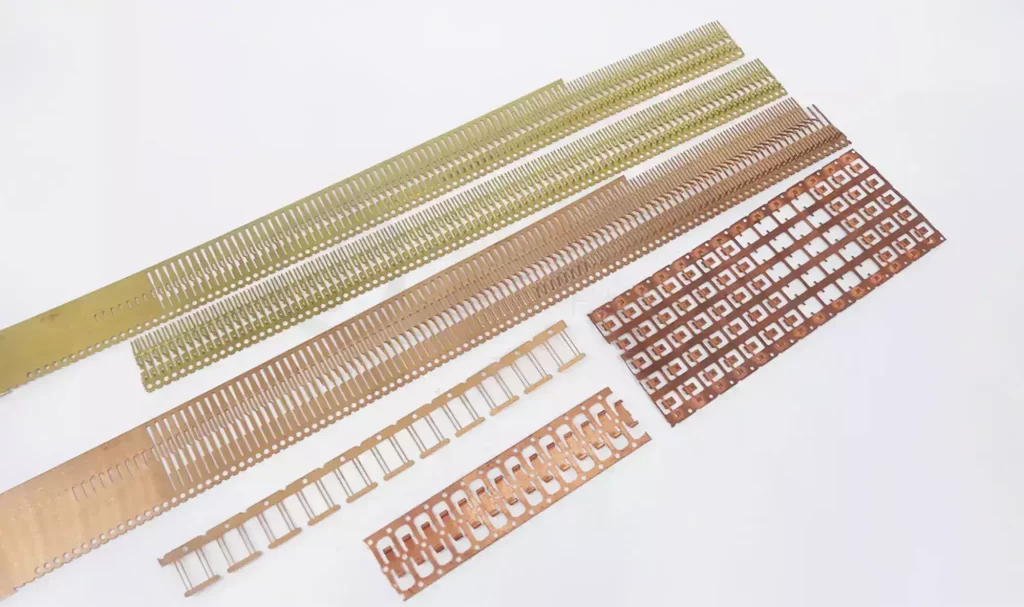

Metal Stamping Parts:

Once dies assembled, the progressive die stamping process begins.

The stock strip is fed into the die set,and as it progresses through the stations, each operation is performed sequentially.The operations may include blanking, forming, embossing or any other required processes for the specific stamping parts design.With each stroke of the press, multiple parts are simultaneously stamped from the stock strip.

Package and Ship:

After progressive stamping process complete, parts inspected quality and compliance with specifications. approved, carefully packaged and prepared for shipment to the customer.

Progressive Die Stamping Services from U-Need

Progressive die stamping services cater to various industries and applications,such as, electrical connectors, automotive components, appliance parts, custom electronic enclosures, fasteners and hardware, medical device components, custom consumer goods parts, aerospace components. And progressive die stamping is suitable for producing a wide range of stamped metal parts, including but not limited to: Copper Busbars, Compression Limiters, Crush Bushings, Fuse Boxes, Fuse Clip, Stainless Steel Hose Clamps, Lead Frames, Selective Plated Lead Frames, Transmission Lead Frame, Lighting Components, Press Fit Pin, Printer Cartridge Blades, Roller Bushing, Selective Plated Terminals, Sensor Components, Shields, Terminals, Contacts, and Connectors, Wire and Cable Connectors, Wire Formed Fasteners, Wire Formed Hooks, Wire Formed Terminals.

At our company, we specialize in providing progressive die stamping services. With our state-of-the-art equipment, experienced team, and commitment to quality, we deliver precision metal stamping parts that meet your exact specifications. From progressive die design and tooling to production and inspection, we ensure that every step of the progressive die stamping process is executed with precision and efficiency.

Contact us (E-mail: info@uneedpm.com) to discuss your project requirements and benefit from our expertise in progressive stamping die. We look forward to delivering high-quality parts that meet your needs and exceed your expectations.