| Die Name Item |

Item |

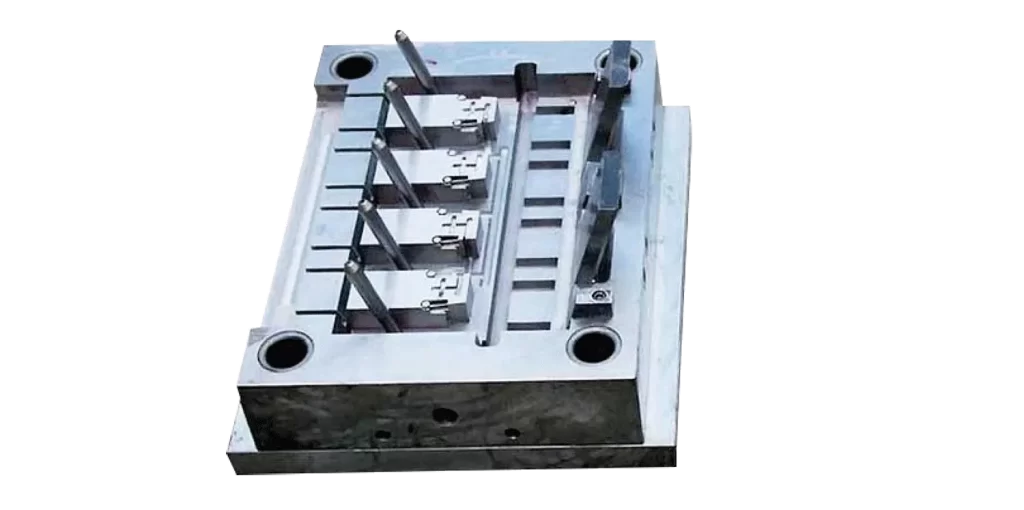

Transfer Die Stamping |

|

Process Principle

|

- The metal strip is fed into the machine.

- During the forming process, the part attached to baseband.

- After the part finished, the separated from the strip.

|

- The metal strip is fed into the first station where the blank is cut.

- The part is free from the base strip.

- The part as an individual unit undergoes various forming stations.

|

| Equipment |

Progressive die stamping involves moving parts through a series of “progressive” stamping stations within a single machine. |

Transfer die stamping may carry out by multiple presses or using a single press. |

| Advantages |

- High speed:

Products can be produced at faster production speeds due to the automated process.

- Low labor:

Only requires one setup to produce completed parts with saving time and reducing labor costs.

- Minimal scrap:

Progressive die stamping uses continuous metal strips with less scrap.

- Repeatability:

Progressive die stamping machines can offer high rates of repeatability repeatability.

- Mass production:

Progressive die stamping can quickly produce large runs of small and/or complex geometries parts with tight tolerances.

- Low costs:

high speed, low labor, repeatability, and mass production mean that parts can be produced at low costs.

|

- Adjustable parts:

Due to the part free from the metal strip, it allows the part to be moved around in a free state and to be manipulated at various angles.

- Versatility:

Transfer die stamping allows for a wider range of operations with more flexibility like cutouts, holes, ribs, threading and knurls.

- Large part production:

Transfer die stamping systems allow large parts to be handled and formed at rapid speeds.

- Cost-effective:

Transfer die stamping uses single or multiple dies that often offer the benefit of lower tooling costs and is more cost-effective for short production runs.

- Reducing labor:

Transfer die stamping don’t need secondary operations for specialized parts.

|

| Disadvantages |

- Limited operations:

Progressive die stamping can perform certain types of operations. For example,adding certain features like cutouts, ribs or threading may require secondary manufacturing processes, which will increase production costs. It is also not suitable for parts requiring deep drawing.

- Part limitations:

The part have to be run on a continuous feed. This means that parts cannot be manipulated freely or independently without additional manufacturing steps.

- Long setup time:

The setups of progressive stamping die must be configured for each project, and reconfiguring the setup for new projects can take significant time. This makes it difficult to switch between projects quickly.

- Expense:

Progressive die systems typically cost more than transfer die systems.

|

- Size costs:

Transfer die stamping can be used to perform smaller parts, but it is less cost-effective than progressive die stamping.

- Scalability:

While transfer die stamping can be automated, it is not cost-effective for large production runs.

|

| Applications |

Progressive die stamping is ideal for applications that require large quantities of small parts. |

Transfer die stamping is best used for large parts that need to undergo multiple processes, such as shells, frames and structural components, and intricate part, such as threading, cutouts or ribs. Transfer stamping is also used to manufacture deep-draw components, it is the ideal operation for manufacturing tube applications. |

| Materials |

Various metals as the base material can be used in progressive die stamping. Steel, aluminum, copper, stainless steel, and brass are all commonly used. A range of noble metals, titanium, and Inconel are also used. Even non-metallic components can be fabricated with progressive |

Transfer die stamping can fabricate parts with many non-ferrous and ferrous materials. Aluminum, brass, copper, Inconel, stainless steel, and noble metals are all common base materials |