Pillar Pins

Mold Bases

Plastic Pillars

Plastic Column Bases

Plastic Round Standoff Columns

This product, made of POM, is used as the components of jig and fixture machine or injection moulding machine parts.

What is POM material?

1. POM, shorted of Polyoxymethylene plastic or Polyformaldehyde, is a a kind of linear polymer structure without side chain, high density and high crystallinity.

2. POM has good fatigue resistance and impact strength, suitable for manufacturing of precision gears subjected to periodic cyclic loads.

3. Good creep resistance. Compared with other plastics, POM has less creep over a wide temperature range and can be used as sealing parts.

4. Good wear/abrasion resistance. POM has self-lubricating property and low friction coefficient, which makes it used as rotating shaft bearing.

5. Good heat resistance. The mechanical properties have little change of long-term use at higher temperatures. The working temperature of POM homopolymer is 100 ℃, and the working temperature of POM bcopolymer can be 114 ℃.

6. Low water absorption. It is not sensitive to the presence of moisture during molding processing.

Product Details

| Material | POM plastic |

| Hardness | Standard |

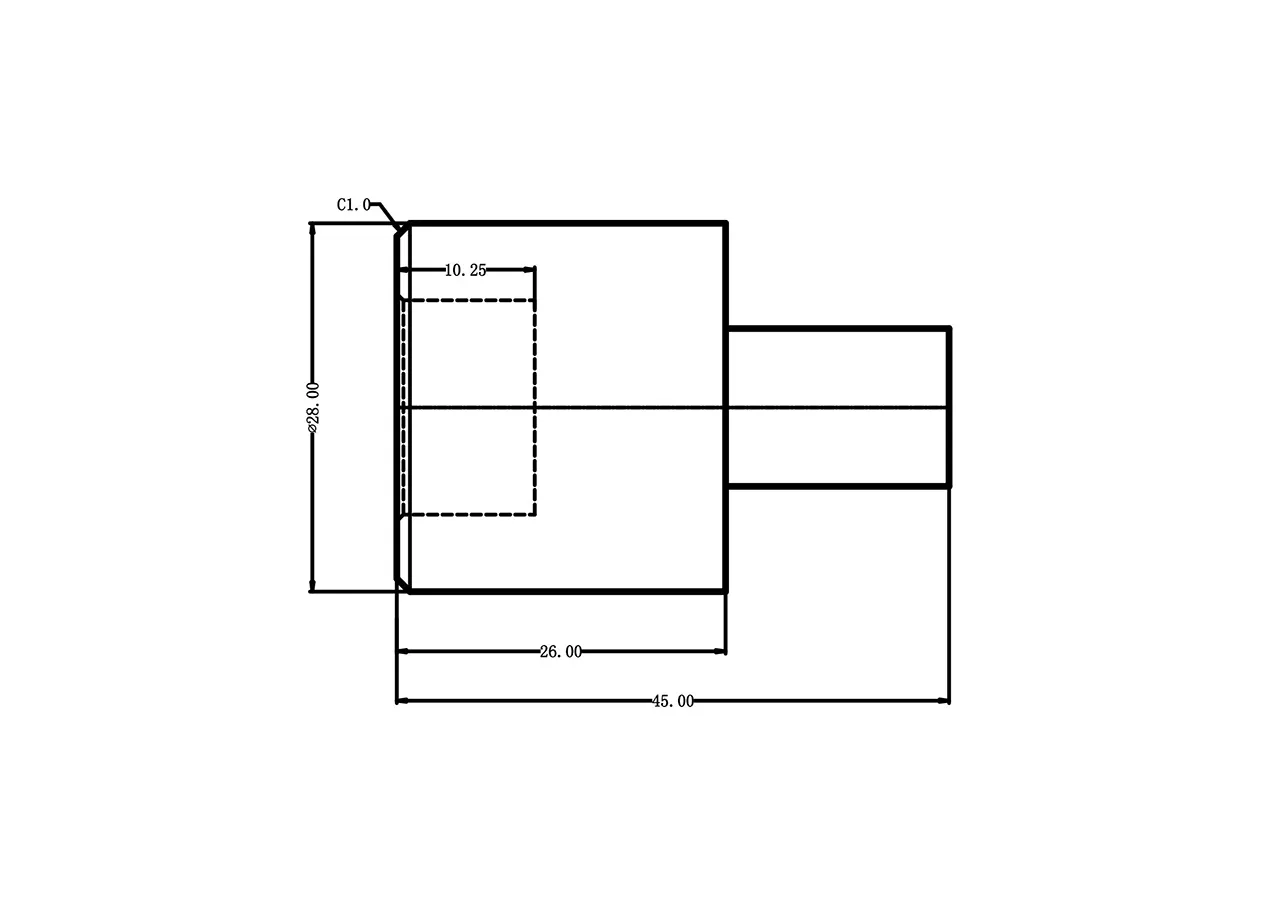

| Overall dimension | Φ28xΦ12x45mm |

| Tolerance | ±0.02 or Customized |

| Roughness | Ra1.2 or Customized |

| Surface treatment | / |

| Quality Assurance | Full scope inspections |

| Testing Equipment | Digimatic Caliper, Micrometer tool,Digital height Gauge |

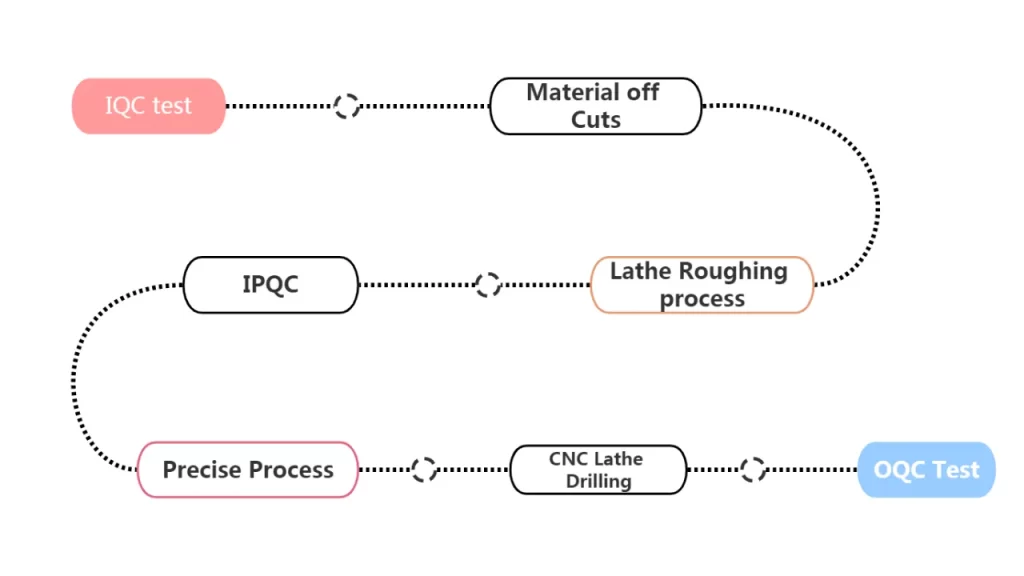

Outline Drawing & Production Procedures

Application of the Turning Parts

Industrial Equipment

Agricultural Machinery

Medical Equipment

Automobile Spar

Parts Food

Toy

Packaging & General Terms

Sample: Acceptable

Production Type: OEM or ODM

Place of Origin: Dongguan, China

Delivery Term: 35 days for mold and samples, after confirmation of samples, mass production time is 25 days

Transportation Time: 3~7 Days

Trade Type: FOB or EXW

Payment: T/T